|

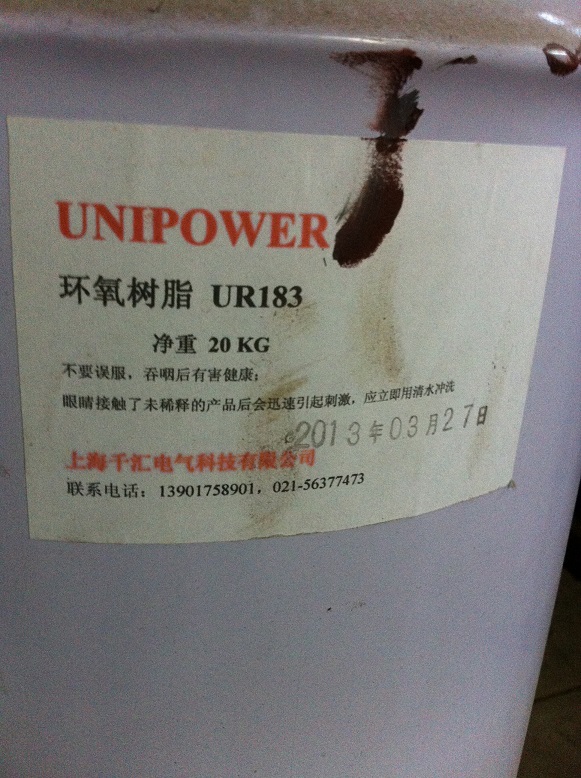

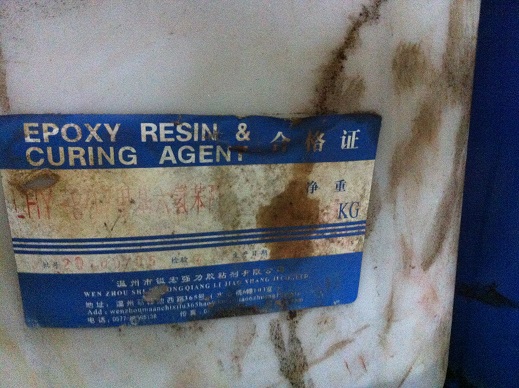

Epoxy resin SZ-9216 100pbw

Bi-component Epoxy resin system / Liquid

Medium&high voltage electrical insulation parts

Test systems:SZ- 9216 /GH-9216/Filling Mixture ratio:100/100/300 Cure conditions:80℃×4hours+140℃×10hours

should be treated immediately by flusing with clean,running water for 10 to 15 minutes.A doctor shuold then be consulted.Material smeared or splashed on the skin should be dabbde off,and the contaminated area then washed and treated with a cleansing cream (see above).A doctor should be consulted in the event of severe irritation or burns.Contaminated clothing should be changed immediately.Anyone taken ill after inhaling vapours should be moved out of doors immediately.In all case of doubt call for medical assistandce.

|

|

PRODUCTS LIST

Home > Product Show

INTRODUCTION

PREVIOUS:Hot Air Circulation Electric Oven

NEXT:Silicone Release Agent